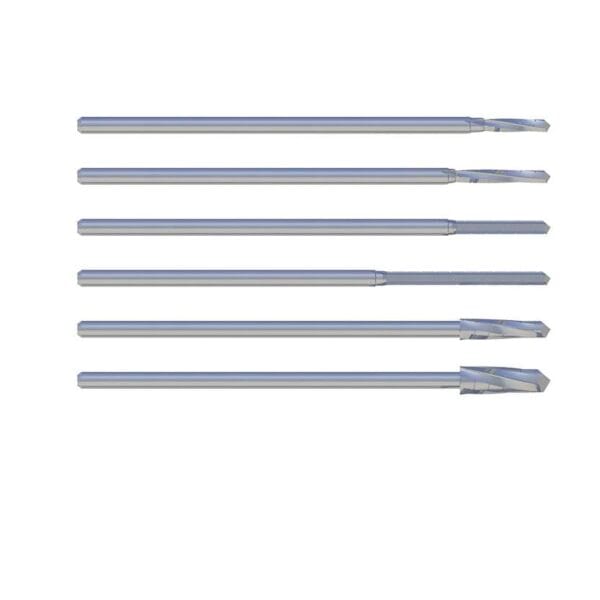

Custom Medical Bur by ZorayPT

ZorayPT’s medical bur is a precision-engineered tool designed for versatile cutting and shaping in a wide range of medical procedures, ensuring safe and accurate performance. As a leading one-stop OEM/ODM manufacturer, with all in-house plastic molding, metal processing, and cleanroom assembly, we deliver superior quality custom medical burs with diameters ranging from 2.0mm to 6.0mm (customizable), lengths from 50mm to 150mm (customizable), and a standard shank of 6.35mm (customizable). Produced in our ISO 13485-certified Class 100,000 cleanroom, these medical burs offer a variety of tip styles, including Round, Ball, Fluted Round, Barrel, Pear-shaped, Cone, or fully customized to meet specific medical needs. This device is ideal for medical cutting and shaping, providing precision and reliability in procedures such as bone cutting, tissue preparation, and implant preprocessing across specialties. ZorayPT can tailor medical burs based on client-provided samples, drawings, or specifications, offering advanced manufacturing processes such as Multi-faceted grinding, Marking, Bending, Drilling, Head forming, Taper reduction Flaring, Threading, Chamfering, Flanging, Grooving, Flattening, Diameter changing, Developing, Polishing coating, Syringe base, Base mold, and Die casting mold. Need a tailored design? We can develop custom solutions to meet your exact requirements. Ideal for various medical applications, ZorayPT provides OEM/ODM solutions with faster lead times and cost-efficiency. Trust ZorayPT for your medical bur needs in advanced medical procedures.

Key Features

- Tip Styles: Round, Ball, Fluted Round, Barrel, Pear-shaped, Cone, or customized.

- Diameter: 2.0mm to 6.0mm, customizable.

- Length: 50mm to 150mm, customizable.

- Shank: 6.35mm, customizable.

- Precision Design: Engineered for efficient medical cutting and shaping.

- All In-House: One-stop production guarantees superior quality.

Applications

ZorayPT medical burs are ideal for:

- Medical Procedures: Efficient cutting and shaping across specialties.

- Bone Cutting and Tissue Preparation: Precise performance in various surgeries.

- Implant Preprocessing: Ensures accuracy with customizable tip styles.

With ISO 13485 standards and faster lead times, we provide cost-efficient solutions. Contact us to customize your medical bur.

Why Choose ZorayPT?

- One-Stop Manufacturing: All in-house plastic molding, metal processing, and cleanroom assembly.

- ISO 13485 Certified: Meets global standards in a Class 100,000 cleanroom.

- Superior Quality: Precision burs for medical excellence.

- Faster Lead Times: Automated production for quick delivery.

- Cost-Efficiency: Integrated manufacturing reduces costs.

- Advanced Customization: ZorayPT can customize burs based on client-provided samples, drawings, or specifications, offering processes like Multi-faceted grinding, Marking, Bending, Drilling, Head forming, Taper reduction Flaring, Threading, Chamfering, Flanging, Grooving, Flattening, Diameter changing, Developing, Polishing coating, Syringe base, Base mold, and Die casting mold.

Enhance your medical procedures with ZorayPT’s solutions. Contact us today!

Medical Bur Specifications

| Parameter | Details |

|---|---|

| Tip Styles | Round, Ball, Fluted Round, Barrel, Pear-shaped, Cone, or customized |

| Diameter | 2.0mm to 6.0mm, customizable |

| Length | 50mm to 150mm, customizable |

| Shank | 6.35mm, customizable |

| Application | Medical procedures, bone cutting, tissue preparation, implant preprocessing |